(This presentation was prepared for an EPC contractor for presenting to management in the year 2003 as a part of proposal)

The Project

12 MW Integrated Gasification Combined Cycle Power Plant

Project Profile

Gross Generation – 12.0 MW(Site Conditions)

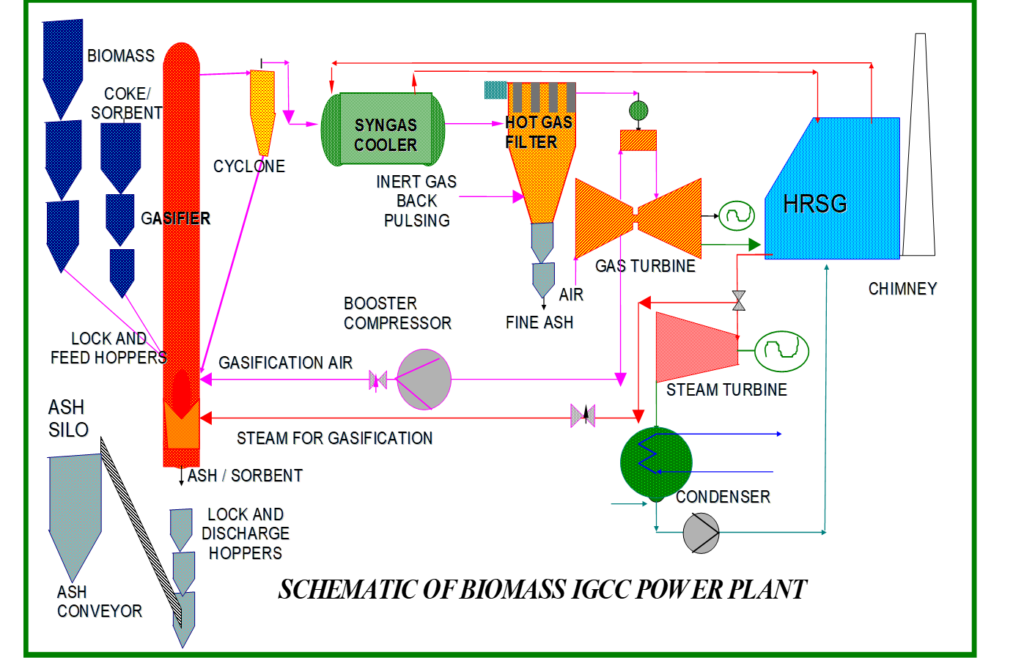

Plant Configuration – Gasifier + Gas Filter + Gas Turbines + HRSG + Steam Turbine and associated Balance of Plant Equipment

Location – Andhra Pradesh.

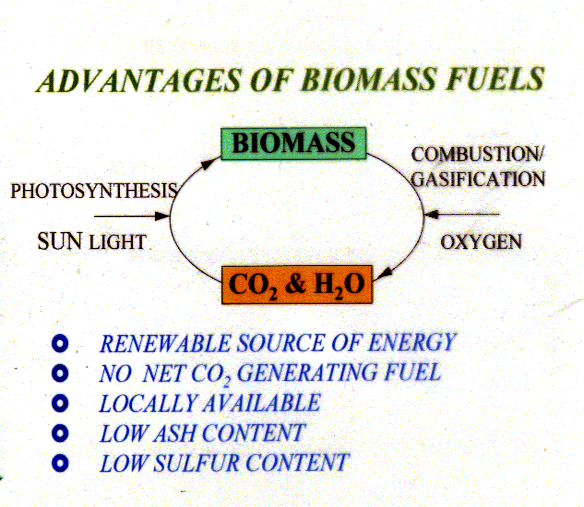

Fuel – Wood & Woody Waste, Coconut / Oil Palm Leaves & stems, Oil Palm Bunch & Fiber, Coconut Fiber (Fuel samples tested in the gasifier at the laboratories in Finland.)

Fuel Source – Agro Waste from Fields and Agro based industries in an area of 12 mandals within 25 km radius (Survey done)

Ash – Land filling and as manure

Water Source – Bore well water (Soil Investigation has been done)

Land – about 57 acres of land already procured

Power Evacuation – 132 kV level To APTRANSCO (PPA has been signed)

Project Financing

Project Cost – Approx. 20 Million US$

Financing – Yet to be tied (Promoter claims that he has got in-principle sanction from Bank)

Sponsor’s equity in place

MNES subsidy is expected on successful commissioning which will meet the escalation cost

Better IRR for a 15 year period and will improve once recent amendments of tax benefits are utilized

A comprehensive package of insurance coverage is being provided to the satisfaction of the lenders

CDM benefits

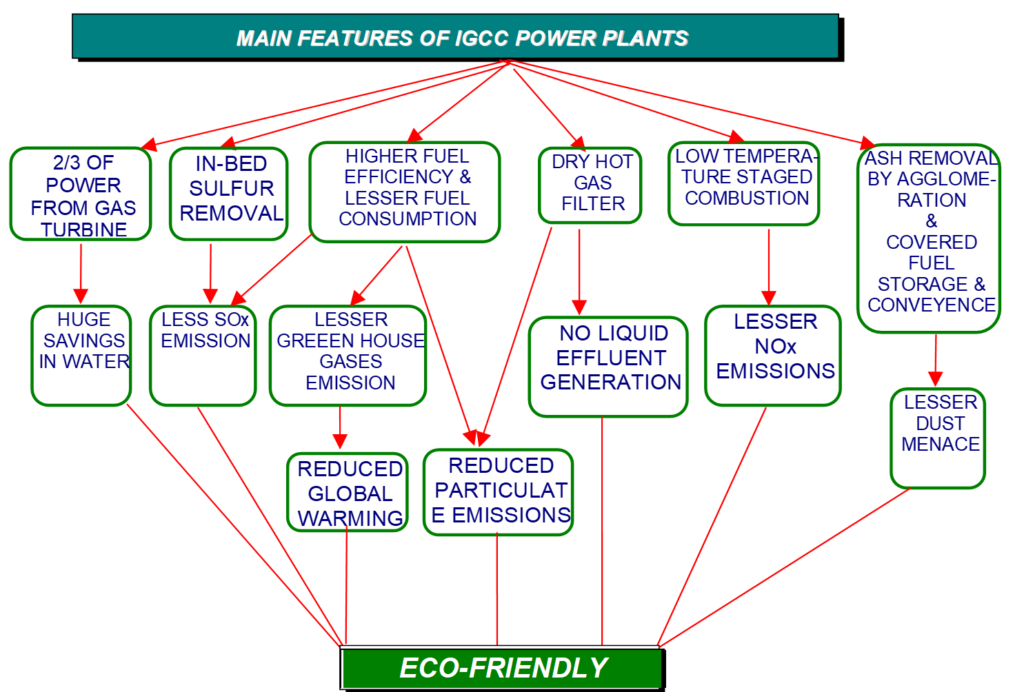

The IGCC Process

The Technology for the Future

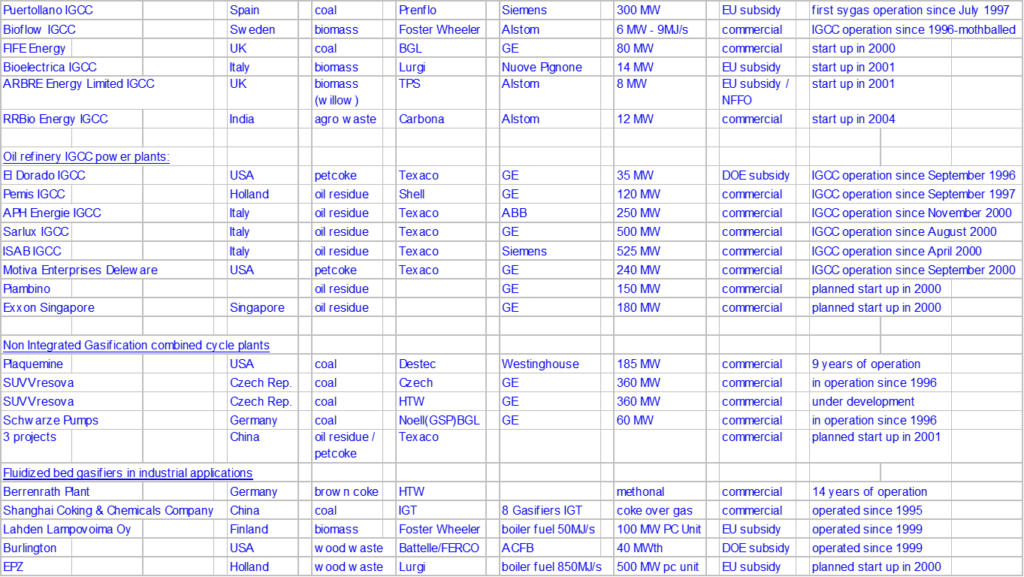

Worldwide IGCC Installations/Constructions

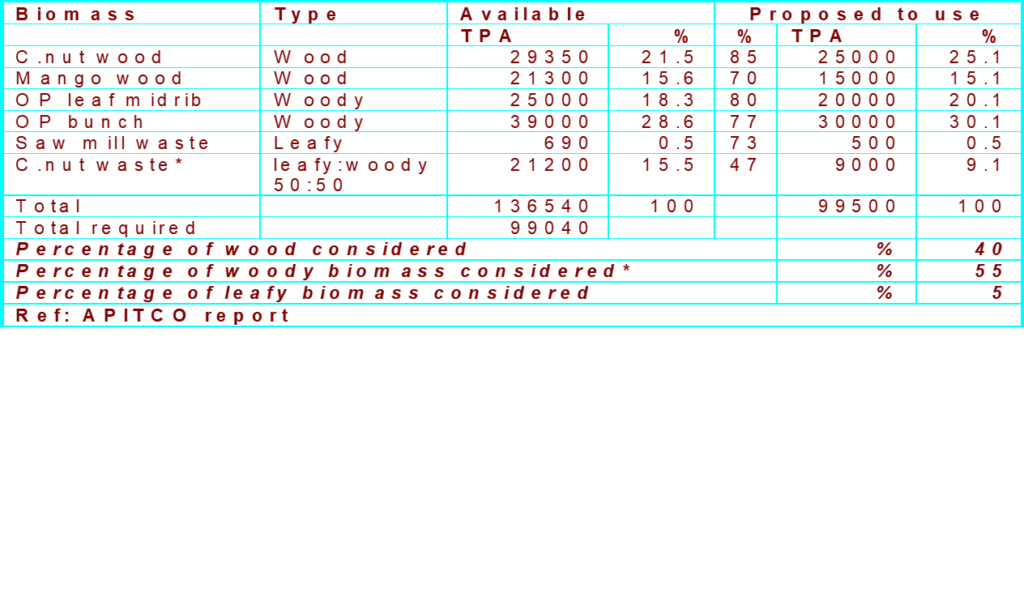

Biomass Fuels

Biomass proposed to be used in the IGCC Power Plant

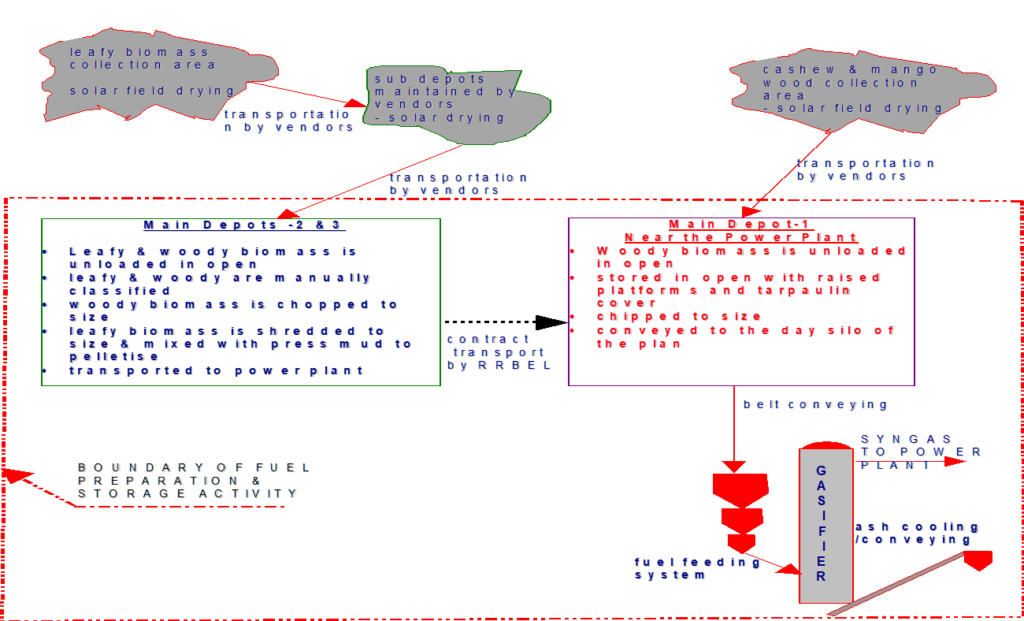

Biomass Handling System

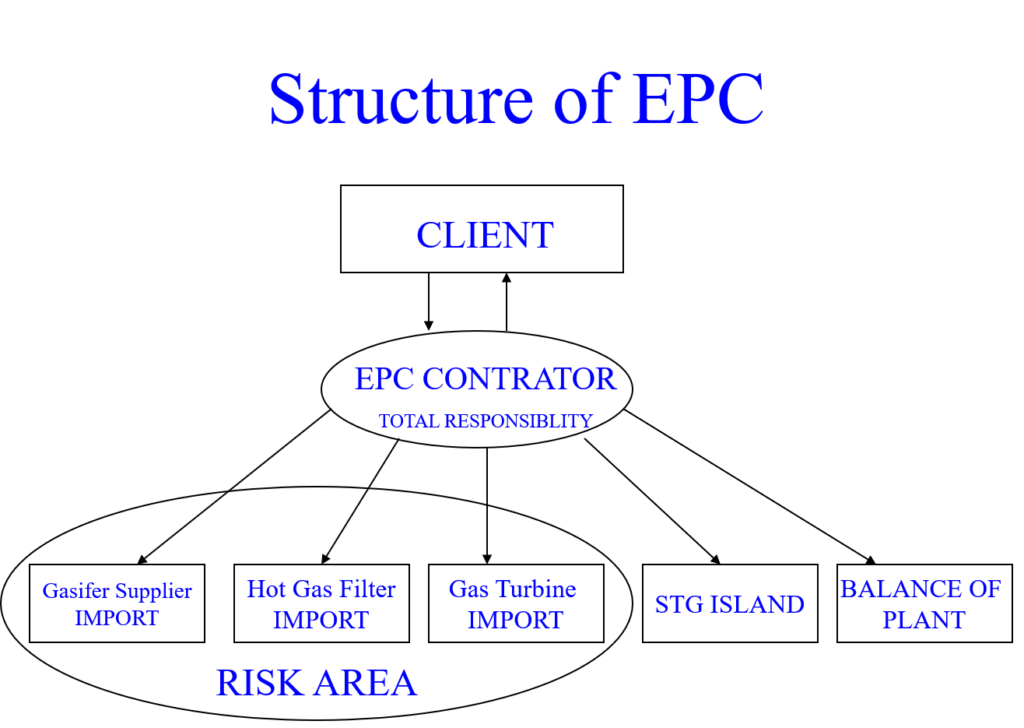

Engineering, Procurement & Construction (EPC)

Scope of EPC

Total Engineering, Supply, Erection, Testing and Commissioning of IGCC Plant including Gasifier, Hot Gas Filter, Gas Turbines, HRSG, Steam Turbine, Biomass Storage &Handling System and associated Balance of Plant systems

Project Management Activities pertaining to EPC

Clearances like IBR, Electrical Inspectorate Clearance etc.

Performance Guarantees including Power Output, Heat Rate, Auxiliary Power Consumption, Plant Availability

Construction Power & Water

Supply of 2 years operating spares for the plant

Unit characteristic test demonstration as per PPA

Completion of Plant Erection and start up in 18 Months and trimming and fine tuning to achieve rated performance within next 6 months.

Liabilities for non-performance including the risk related to Gasfier, Hot Gas Filter and Gas Turbine

Bonus Clause is there for better performance

EPC Risk – Technology

IGCC technology for Indian fuels and conditions not yet proven in a commercial plant

Gasifer for biomass is proven in non-commercial pilot plant (Varnamo biomass demonstration 6 MW IGCC Power Plant, Sweden)

Biomass preparation and handling

Gas turbine integration in a commercial biomass plant is not yet proven

Performance of Hot Gas Filter for biomass fuel

Availability guarantees as expected by the promoter 8000 hrs (more than 90%) for the Indian biomass fuels in IGCC route is to be reviewed

Extra exposure to liabilities due to the account of Gasifer, Filter and Gas turbine supplier non-performance

Other EPC Risks & Mitigating Factors

Cost Overruns – Fixed price EPC construction contract; all change order to be approved;budgeted contingency

Construction Delay- LD for delay in completion; budgeted contingency

Plant Performance – Stringent LD clause for the sub-contractors

Force Majeure – Risk Insurance

Project Defects – Trimming period of 6 months and 1 year warranty period

Operation and Maintenance (O&M)

Scope of O&M

Involvement during the commissioning of the plant for the smooth takeover

Complete Operation and Maintenance of the facility from takeover

To Provide adequate trained man power for O&M

Development of O&M management system

Preparing an annual operating plan

Developing monthly power generation report

Planning of shut down and maintenance schedules

Attending Minor/Major breakdown of power plant equipment

Attending to unscheduled maintenance as and when required

Major and Minor Overhauling of Power Plant equipment & auxiliaries

Obligation of the Promoter for O&M

Providing all tools & tackles including special tools, Welding & Gas cutting equipment, workshop facilities, Chemical lab, Testing instrument & equipment

Providing Fuel, Water, Compressed Air, Spares and all consumables

Providing Furnished Office with required facilities including plant communication system

Providing Free furnished accommodation, Boarding and local transport to O&M staff

All Statutory formalities for operating the plant

Providing secure on-site warehousing facilities for tools and spare parts

Unskilled personnel

O&M Risks & Mitigating Factors

Plant Availability – To be addressed carefully because of Technology Risk

Plant Output –

Plant Efficiency – Preventive Maintenance

Force Majeure – Risk Insurance

Environmental Compliance – Project designed to meet environmental regulations; no unusual high-risk environmental considerations

Fuel Supply – Farm insurance contemplated, Alternate fuel (Coal, RDF & HSD) supply considered

O&M Cost

The compensation for O&M shall be based on of annual turnover on a minimum guaranteed exportable power of 86.5 million units.

The above compensation is excluding the cost of spares.

The liability for not meeting the minimum generation is 5% of generation cost with a maximum cap of 15 % of annual turnover.